LFC-1 Prototype 1

The first version of LFC-1 was designed and build in under 10 weeks using a CNC mill and 3D Printers. I designed a simple focusing mechanism that would slide linearly with the push of a small lever on the bottom of the camera. A helical focusing system was used in later iterations of this prototype.

Prototype 1 Images: Design includes CNC milled rear standard, Schneider 90mm leaf shutter lens, Acrylic ground glass, and 3D printed handle, bellows, ground glass holder, and film holder.

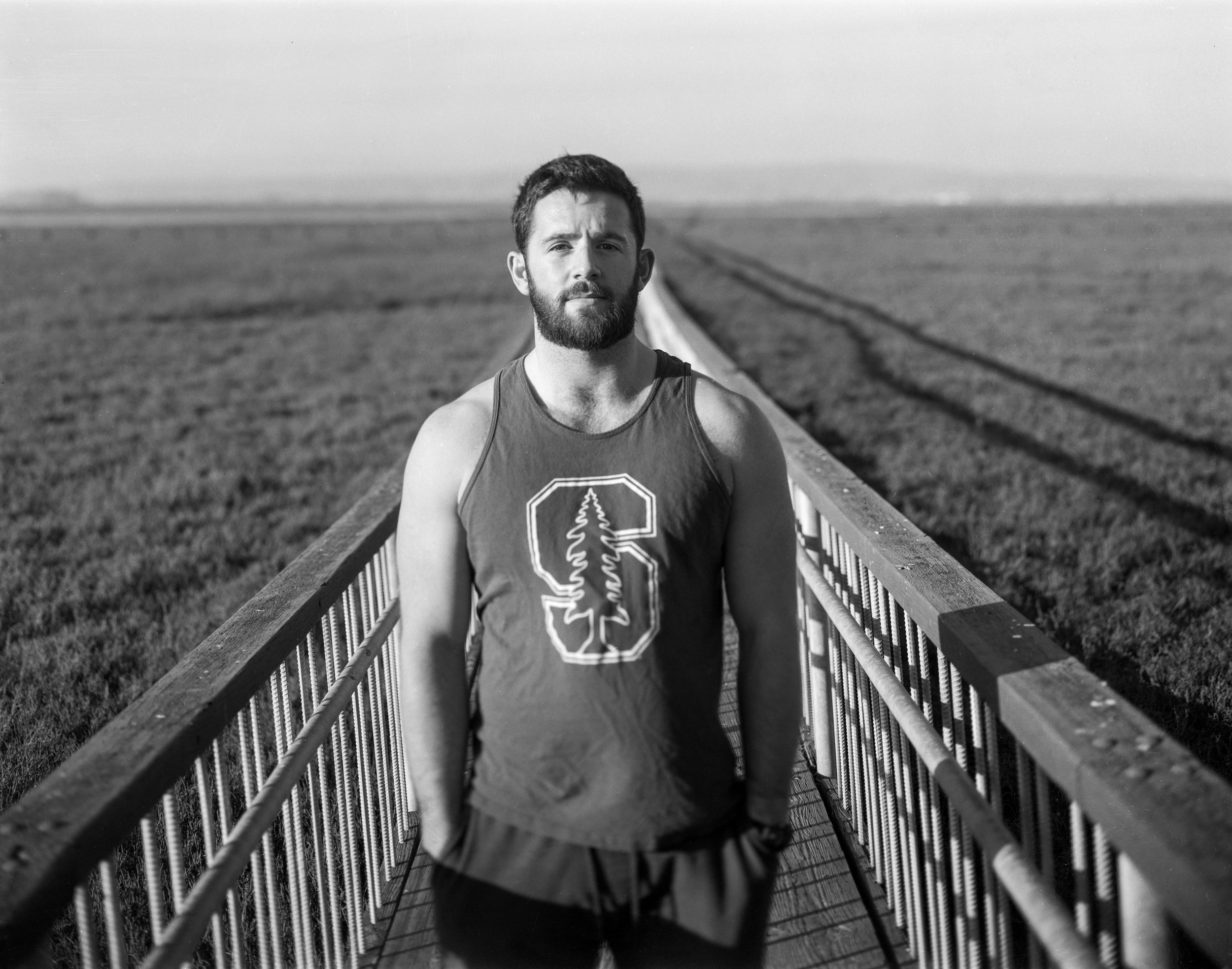

4x5 Sample Photos

Shot with LFC-1 and a variety of standard 4x5 cameras

The CNCing Process

I used a total of 10 different tools to machine the rear body of Prototype 1 of the LFC-1. Starting with a 8x8x1” aluminum block, I faced the sides with the shell mill, before performing the main milling operations on the top side of the part. This was done with 1”, 1/2”, and 1/4” flat end mills, single lip cutters (for the logo), a chamfer end mill, two T-Slot cutters, and 8-32 drilling and tapping tooling.

This is the bare chassis of Prototype 1 after bead blasting but before polishing the exterior and integrating major components.